21 september, 2022

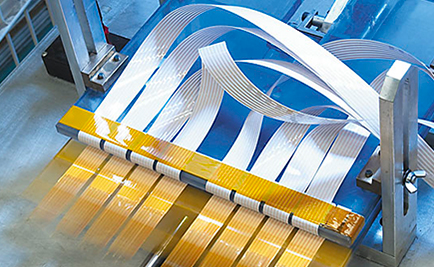

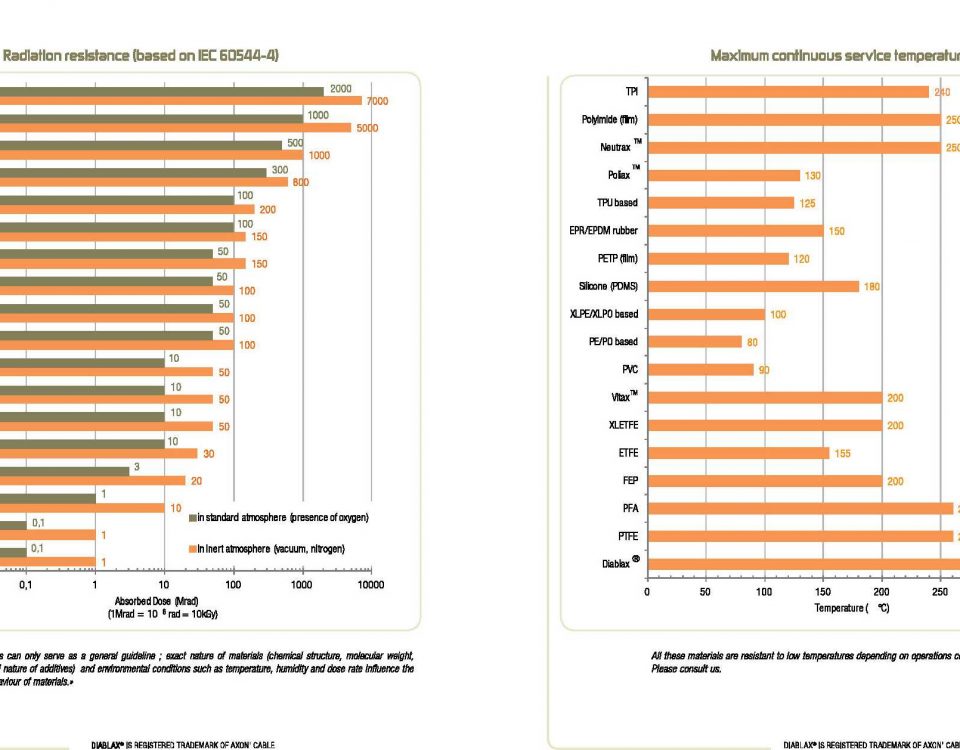

We now offer wider range of products insulated with PTFE, ETFE, FEP or polyimide for needs that have extra tough requirements like temperature resistance from -90°C to +260°C, excellent dielectric and aging characteristics, radiation resistance, extreme flexibility etc. Available in different types including single-stranded, multi-stranded, extruded, taped, shielded or jacketed versions, they will meet all the requirements. Contact our sales team to learn more.